Forging

General Information

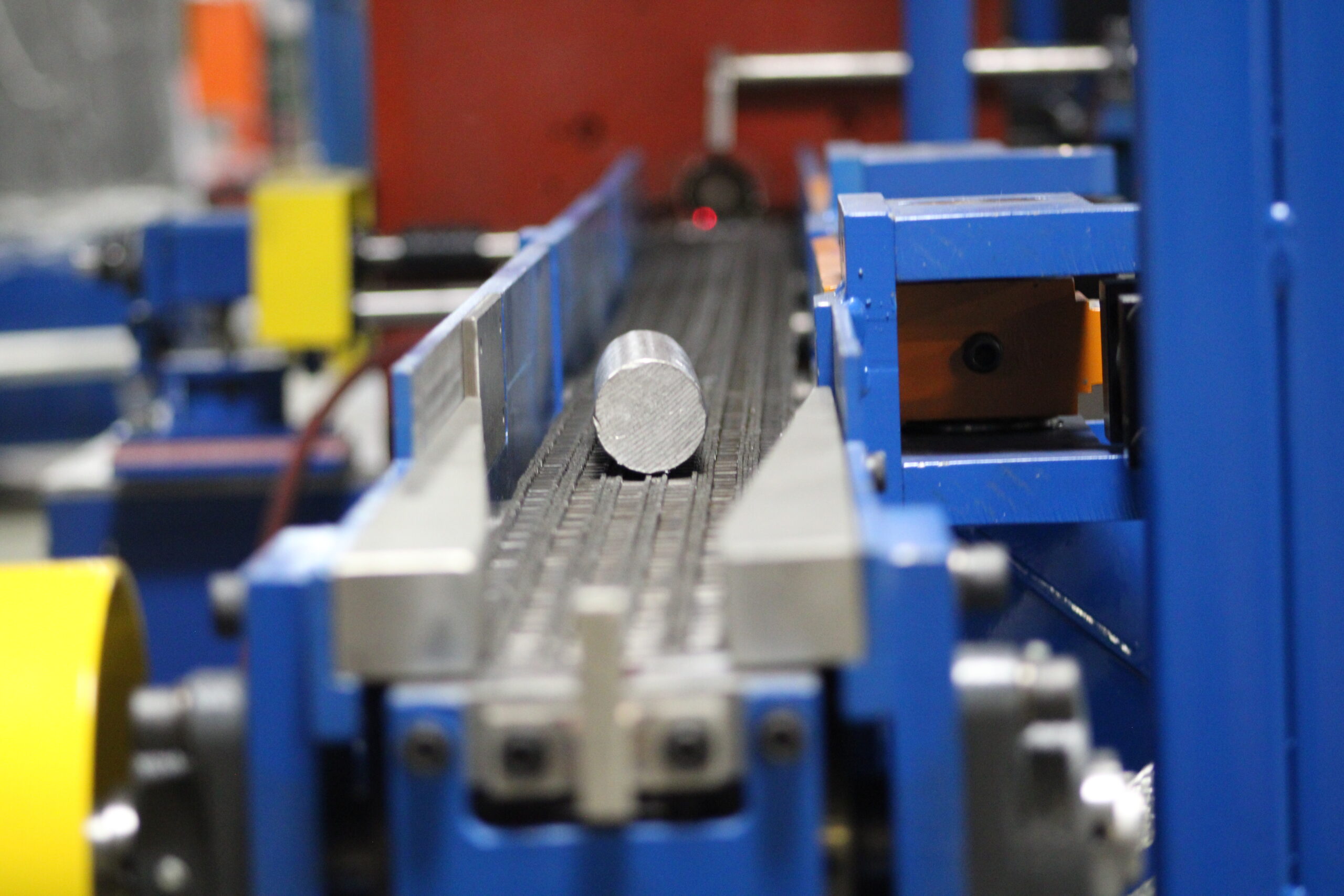

We offer complete automation with auxiliary equipment including bin tippers, bowl feeders, step feeders, pinch roll drives conveyors, hot end handling, ancillary equipment, cooling systems including pump stations, input transformers and robots.

Interpower Induction is the leading provider of induction forge heating machines in the USA. We provide complete turnkey systems that will perform to the customers exact specifications.

Billet, Bar End, & Bar Heating Machines

Interpower builds quality induction heating machines to heat billets, bar end and bar heating solution to fit the specific needs of your forging project challenges.

Advantages include:

- Advanced PLC control, power and temperature control

- Quick release connections for power and water

- Heavy-duty construction for tough forging conditions

- Bar end heaters with solenoid coil, multi stations, skid coil or choval coil for horizontal/vertical upsetting, swaging, thread rolling, piecing, and heading application