Sign-Link™ Quality Monitor

General Information

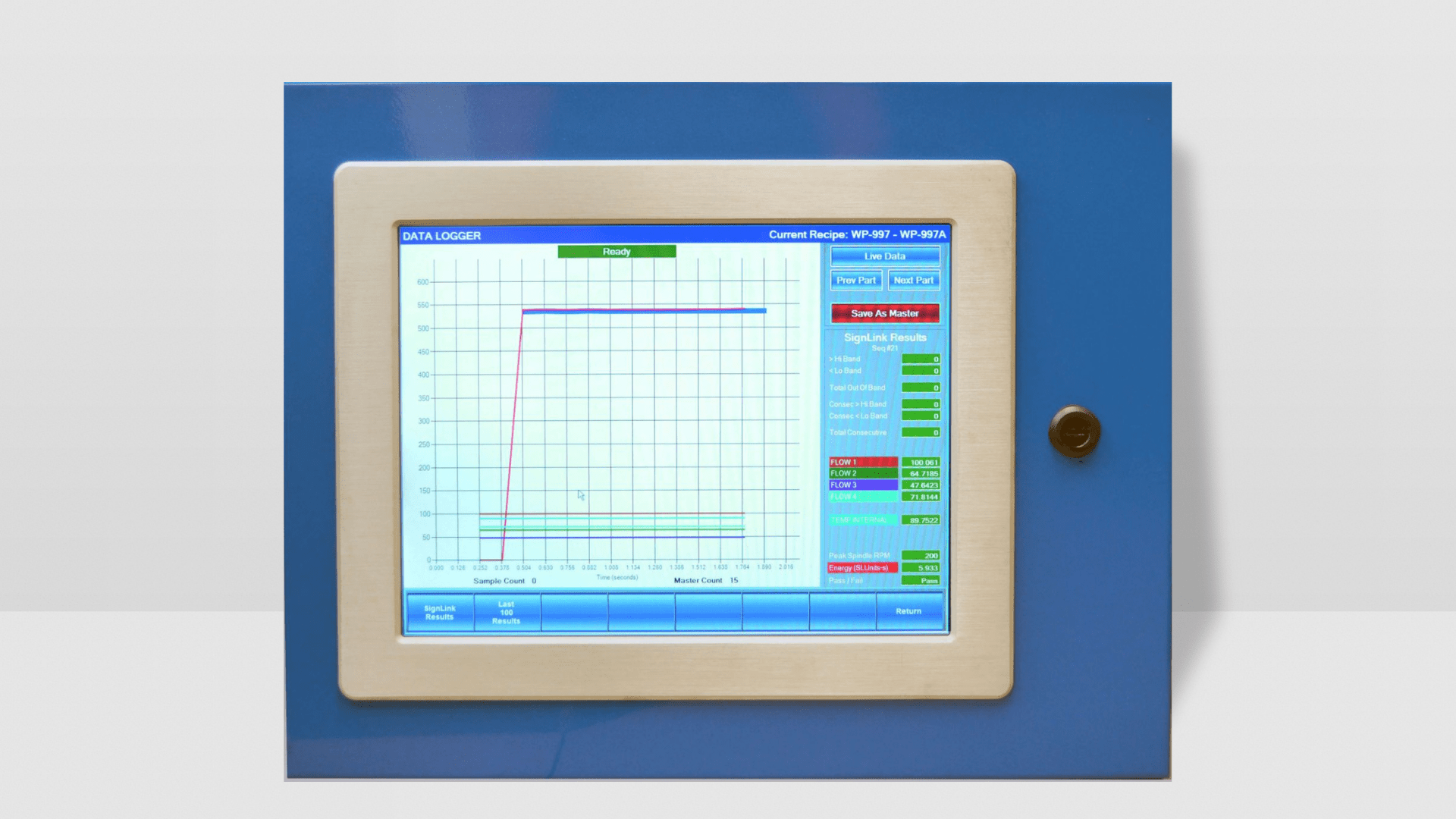

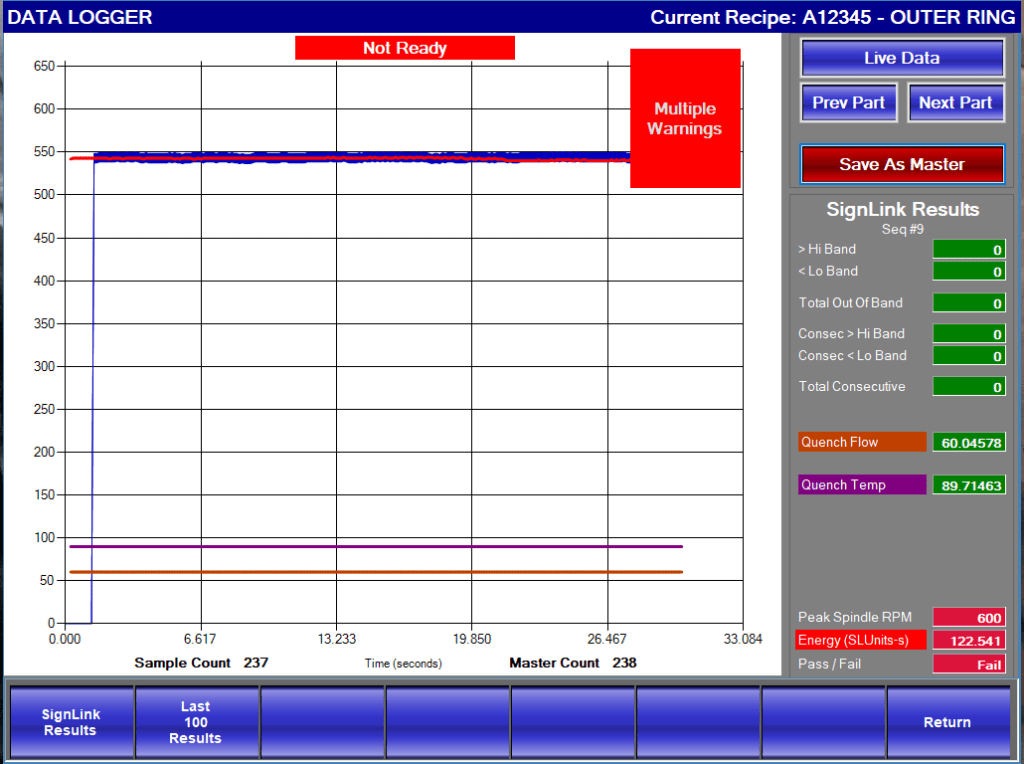

The monitor is “taught” what a good part is, creating a “master signature”. Once a master is made, all other parts are compared against the master in real time. This data includes part number, part name, volts/amps/kilowatts, pass/fail status, quench flow, quench temp, part rotation, time, date, and all signature intervals. If a part falls out of specification during the heat process, the monitor notifies the user of the discrepancy through a color touch screen and an industrial PC.

Quality Standards

Sign-Link® systems are operating on over 200 induction heat-treating machines in a variety of applications. The system helps companies comply with ISO 9001 and QS-9000 quality programs.